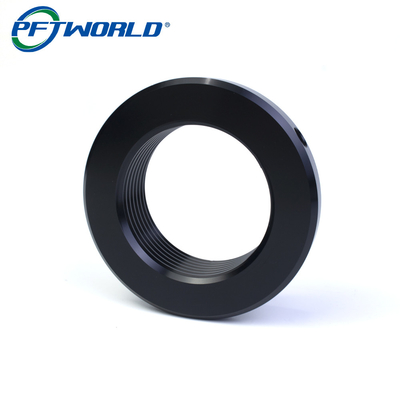

OEM CNC Machined Aluminum Parts Turning Anodized Service For Camera Accessories

Quick details:

1. Keyword: CNC Aluminum Parts

2. Process: CNC Turning Service

3. Color: Customized Colors

5. Application: Camera Accessories

6. Drawing Format: 2D/(PDF/CAD)3D(IGES/STEP)

7. Equipment: CNC Machining Centers

8. Lead time: 1-2 weeks

Specification:

|

Company |

Shenzhen Perfect Precision Product Co., Ltd |

|

Certification |

ISO9001:2015/ISO13485:2016 |

|

Experience |

10+ years' experience in plastic injection mold making and plastic products |

|

Equipment |

High-speed CNC, Standard CNC, EDM, Wire Cutting, WEDM, Grinder, Plastic Injection Molding Machine for trial out mold from 50-3000T available. |

|

Feature |

Nonmarking and non-flash |

![]()

CNC Machining Capabilities

We have a skilled engineering team with expertise in ISO9001, ISO13485, AS9000, and IATF16949 quality systems, along with ERP/MES systems, enabling us to handle one-time prototype and mass production. Our digital factory allows real-time tracking of project progress. We also utilize quality inspection equipment such as CMM and 2D measuring instruments to ensure stringent quality control.

Why Choose Us for Custom CNC Machining?

Superior Service: Our commitment to great service drives our mission.

Quality Assurance: We uphold the obligation to deliver high-quality products.

Extensive Experience: We bring years of production and management expertise to every project.

Rigorous Quality Control: Our professional testing equipment and strict quality control system ensure top-notch quality.

Innovative Design: Our skilled designer team specializes in creating new and unique items.

Customization Services: We offer comprehensive OEM & ODM services to meet your specific needs.

CNC Machining Applications

Housings and Enclosures: Utilized for precision protection of electronic and industrial equipment.

Brackets: Manufactured for mounting and structural support in aerospace, automotive, and machinery applications.

Manufacturing Fixtures: Precision fixtures and tooling to aid in the production process.

Gears and Bearings: CNC-machined for smooth mechanical operations across various applications.

Internal Mechanical Components: Precision fabrication for aerospace and automotive applications.

Medical Instrumentation: Critical CNC machining for producing precise and safe medical devices.

![]()

FAQ:

Q1:Where can I get product&price information?

A1:Send us an e-mail, and we will contact you as we receive your mail.

Q2: How soon can I get samples?

A2: Depending on your specific project, it usually takes 10 to 20 days.

Q3:How to enjoy the OEM services?

A3:Usually, based on your design drawings or original samples, we give some technical proposals

and a quotation to you, after your agreement, we produce for you.

Q4:Can you make machining parts based on our samples?

A4:Yes, we can make measurements based on your samples to make drawings for

machining parts.

Q5: Is it possible to know how are my products going on without visiting your company?

A5: We will offer a detailed production schedule and send weekly reports with digital pictures and videos that show the machining progress.

Q6:Can I get a quote without drawings?

A6:Sure, we appreciate receiving your samples, pictures or drafts with detailed dimensions for accurate quotation.