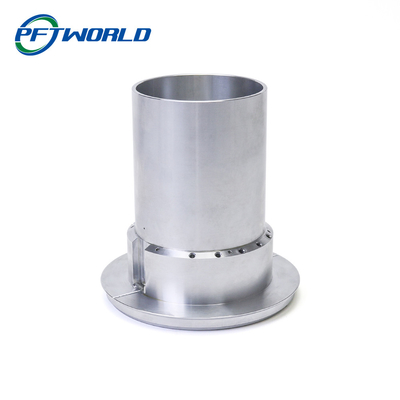

CNC Turning Milling Parts OEM Surface Treatment Aluminum Anodizing And Sandblasting Parts

Detailed introduction:

CNC Machining or Not: CNC Machining

The Technological Process: Sandblasting+ Anodizing

Service: OEM&ODM,Custom

Shipment: DHL, FedEx, TNT, UPS

Payment: T/T down payment

Lead-Time: 2~4 weeks

Tolerance: According to the customer's requests

Turning Features:

Low equipment input cost in the same productivity when the lathe investment is better than that of the grinder, its auxiliary system cost is also low. For small batch production, cutting does not need special equipment, and mass processing of high-precision parts needs to play good rigidity, positioning accuracy and repeated positioning accuracy of high CNC machine tools. Suitable for small batch flexible production requirements lathe itself has a wide range of flexible processing methods, lathe control is a simple and fast vehicle cutting clip, compared with grinding hard lathe can better meet the requirements of flexible production requirements

Description:

Today introduce the product customized sandblasting + instinctive quality of aluminum oxide, The sandblasting principle is too hard tiny silicon carbide grains by sandblasting machine evenly on the impact surface of aluminum products, uniform surface pits, and very small, we are almost invisible to the naked eye, can only see the polished aluminum into matte, Sandblasting is not only to get the surface matte effect so that the product appears more advanced, rich texture but also to prepare for the subsequent other surface treatment process.

After sandblasting processing of aluminum to oxidation next, and the oxide film surface, improve the oxidation resistance of aluminum, and still keep the aluminum frosted effect, tiny burr removing aluminum processing parts, precision parts, in particular, to finish requirement is very high, the tiny burrs will cause the defect of parts, solve the problem of the metal reflective, Thus becoming a high-quality custom aluminum parts

Specification:

| Product range | CNC Injection Molding Shell Frame Parts, Plastic Injection Parts |

| Processing Craft | Mold fabrication, Injection, etc; |

| Material | ABS, BMC, SMC, AS, PP, PPS, PC, PE, POM, PMMA, PS, HDPE, TPE, TPU, etc |

| Surface finish | Polishing finish, Texture Finish, Glossy Finish, Painting, Slik print, Rubber Painting, etc |

| Color | RAL/PANTONE color |

| Size | according to the drawing |

| Mold Standard | DME,LKM,FUTA,HASCO etc. |

| Advantages | Competitive price & Fast Delivery & Good quality |

| Mould Base | as per the customer's requirement |

| Delivery time | 10-15 days after placing an order |

| Tolerance | 0.01~0.1mm; |

| File Format | Solidworks, Pro/Engineer, Auto CAD, PDF, JPG |

| Quality Control | Conducted by ISO9001 System and PPAP Quality control documents |

| Inspection | IQC, IPQC, FQC, QA |

| Application | All kinds of plastic injection parts are being used in a variety of industrial applications. |

| Service |

Warm and quick response service provided by the professional Export Sales Team with many years of experience in handling exports to the US, Europe, Japan, and other countries and regions. |

Attention:

The pictures and prices shown are just for the exhibition of our production. Any more details you want to know are welcome to contact us. We will send you pictures of products more suitable for your inquiry for better reference and then we will quote you. If you are interested, please feel free to contact me: at sales04@7-swords.com

FAQ:

1. What is the delivery date?

Generally, the sample lasts for 1-2 weeks and the mass production lasts for 3-4 weeks.

2. How long can you make an offer after the inquiry?

We will make an offer within 1 day after obtaining some necessary information, such as a 3D drawing, a specific quantity of order, and other details.

3. If I am not familiar with the model, could you give me some professional advice

As long as the customer needs you, our engineers and salesmen will provide you with some professional and relevant advice.

![]()

![]()